NEWS TAG

brand

LVP Wear Layer Thickness Chart: What is A Good Wear Layer for Vinyl Flooring?

When considering new flooring, especially luxury vinyl plank (LVP) flooring, understanding the specifics of wear layer thickness can significantly impact both durability and satisfaction. This guide will help you understand what a wear layer is, its importance, and how to choose the right thickness for your needs, ensuring your flooring stays beautiful and durable for years.

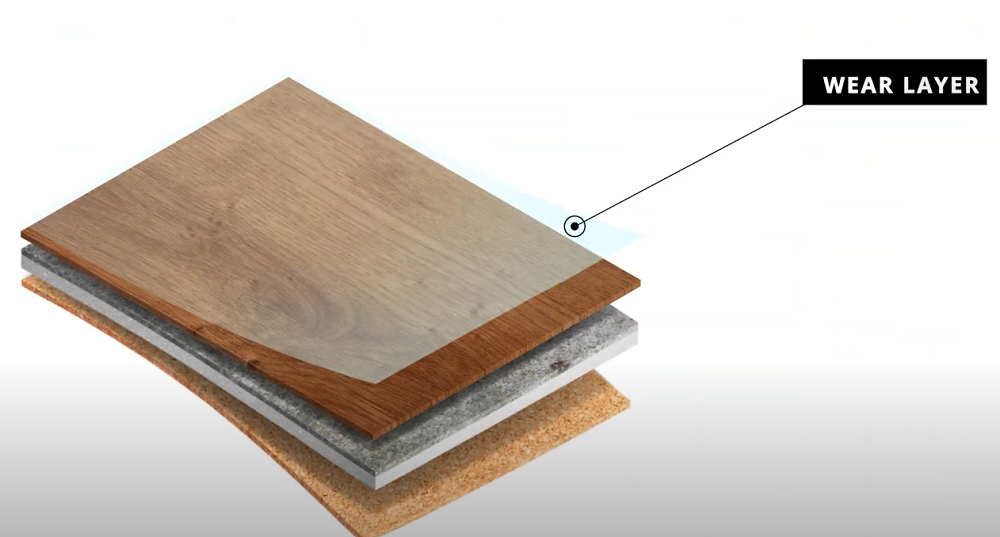

What is the Wear Layer of Luxury Vinyl Flooring?

The wear layer is a crucial component of luxury vinyl plank (LVP) flooring. Essentially, it's a clear, durable coating applied over the decorative surface of the vinyl. This layer is designed to protect the floor from scratches, dents, stains, and other wear and tear. The thickness of this layer varies, typically ranging from 6 mil to 20 mil (a mil is one-thousandth of an inch). The wear layer is often enhanced with materials like ceramic beads to increase durability and provide additional benefits like improved grip.

Why is the Wear Layer Important To LVP Flooring?

The wear layer's primary role is to protect the underlying decorative layer from damage due to foot traffic, furniture, pets, and other everyday hazards. A thicker wear layer generally means a longer lifespan for the flooring because it can withstand more abuse before the decorative layer gets damaged. This is especially important in high-traffic areas where the floor is subject to consistent wear.

Difference Between Luxury Vinyl Plank Floor Thickness & Wear Layer

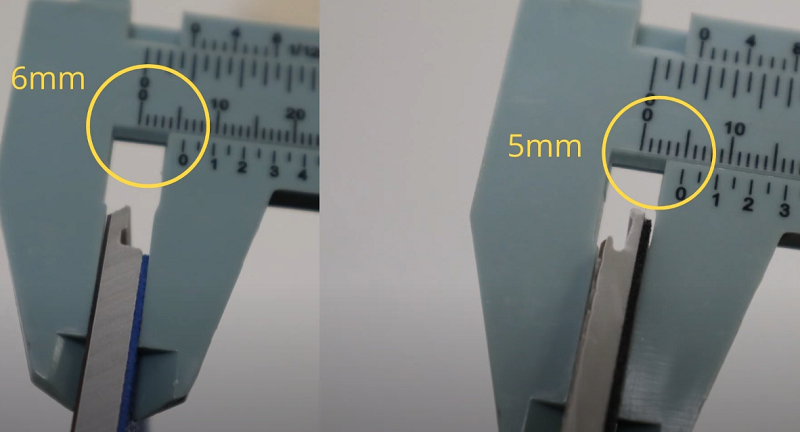

It’s important to differentiate between the overall thickness of the LVP and the thickness of the wear layer:

Overall Thickness: This includes all layers of the LVP flooring, from the top to the bottom, and contributes to the floor's stability and feel underfoot. The total thickness of the floor is measured in "mm", for example 6mm floor with a 1.5mm pad is actually = 4.5mm

Wear Layer Thickness: This is just the top protective layer. While it does not affect the floor's stability, it is crucial for the floor's durability against surface wear. The wear layer thickness is measured in "mils" and 1 mil = 1/1000th of an inch

What's More Important: Wear Layer Thickness or LVP Overall Thickness?

While both aspects are important, the wear layer thickness is more crucial for surface durability. However, the overall thickness can contribute to the feel and noise insulation of the flooring. A thicker overall floor can provide a more solid feel and better sound dampening but doesn't necessarily indicate better surface durability.

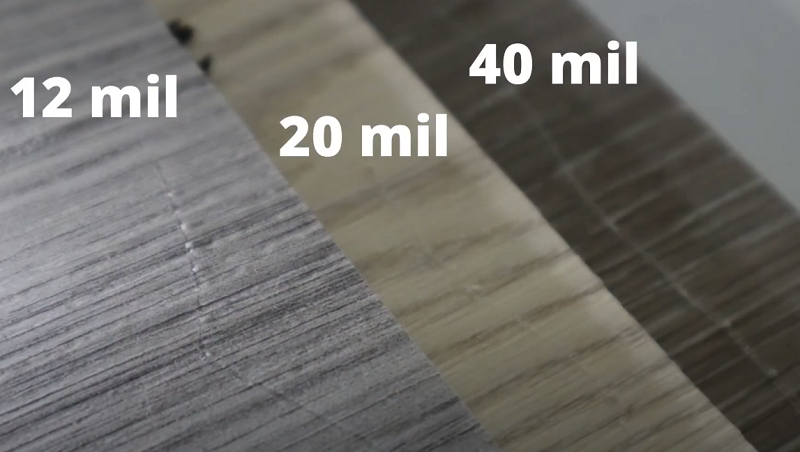

LVP Wear Layer Thickness Chart

Here's a simple chart outlining the typical wear layer thickness for Luxury Vinyl Plank (LVP) flooring:

| Wear Layer Thickness | Durability Level | Suitable For |

|---|---|---|

| 6 mil | Light Residential | Bedrooms, closets |

| 12 mil | Moderate Residential | Living rooms, dining areas |

| 20 mil | Heavy Residential/Light Commercial | Kitchens, hallways, offices |

| 28 mil+ | Commercial/High Traffic | Retail spaces, commercial areas |

Notes:

6 mil: Best for areas with minimal foot traffic.

12 mil: Good balance of cost and durability for most homes.

20 mil: Ideal for high-traffic areas in homes and light commercial spaces.

28 mil+: Designed for heavy commercial use and high-traffic environments.

What is a Good Wear Layer for Vinyl Flooring?

For residential use, a wear layer of 12 mil can provide adequate protection and durability. For commercial settings or homes with high traffic, pets, or children, a 20 mil wear layer is advisable. These thicker layers help ensure the floor remains in good condition longer, resisting scratches and other forms of wear more effectively.

What Mil is Best for Vinyl Plank Flooring?

Choosing the right mil depends on your specific needs:

6 mil: Suitable for light use. Typically lasts around 4-5 years.

12+ mil: Good for residential areas with moderate traffic. Expect about 7-9 years of use.

20+ mil: Commercial-grade, can handle heavy traffic and lasts 10 years or more.

The choice of mil should be based on the expected usage of the floor, the level of activity it will endure, and how long you plan to keep the current flooring.

Expert Advice on Selecting the Right Wear Layer of Vinyl Flooring

To help you find the right wear layer for your vinyl flooring, our expert gives you the following suggestions:

Durability and Protection

As explained by David, co-founder of Charlie's Floors, the wear layer is not just about thickness but also about the quality of materials used, such as ceramic bead coatings, which add durability and slip resistance essential for homes with kids or pets. Embossing and textured finishes can also enhance the grip and natural feel of the flooring.

Practical Insights from Flooring Professionals

Matt Pfeiffer from Northern Wholesale Flooring highlights the importance of not just going for the lowest price but understanding the wear layer's role in flooring performance. A thicker wear layer means better durability and is advisable for families needing a robust flooring solution.

Real-World Customer Experiences

Alan from Cordiller Floors emphasizes that while marketing often highlights wear layer thickness, the actual performance and look of the floor once the topmost coating wears off are more critical. His advice leans towards looking at the overall construction and quality of the floor rather than just the wear layer.

Choosing the right wear layer thickness for your LVP flooring is essential for ensuring it meets your expectations in terms of durability and appearance retention. While thicker wear layers offer better protection, they also come at a higher cost. Therefore, consider your specific needs, the area's usage, and your budget when selecting the flooring. Remember, investing in a thicker wear layer can be more cost-effective in the long run, especially in high-traffic environments.