NEWS TAG

brand

- Home

- Esd Vinyl Flooring Rolls

Anti-Static Vinyl Flooring Rolls - ESD PVC Sheet Flooring

ESD Vinyl Flooring Rolls is also know as Anti-Static Flooring Rolls, which is a seamless floor covering whose style and patterns are constantly updated, comes with antistatic performance (Static-Dissipative or Conductive) making it the most used vinyl flooring product in operating room, manufacturing & assembly workshops of electronic products, telecommunications industry, computer room and other areas that require anti-static floor environment. The Anti-Static Vinyl Sheet Flooring is made up of large rolls without using much labor to cut the material, due to this, there is not much of wastage.

Huiya Supply High-Quality Profitable ESD Vinyl Sheet Floor (Anti-Static PVC Floor Rolls)

Huiya as the specialist of anti-static raised flooring system, can be your best supplier of ESD Vinyl Floor Sheet with rich experiences. Our ESD vinyl sheet floors are gaining popularity, especially with the arrival of new materials whose appearance and finish compare favorably to high-end coverings.

Huiya ESD Vinyl Flooring Rolls (PVC Floor Sheets) Specifications & Features

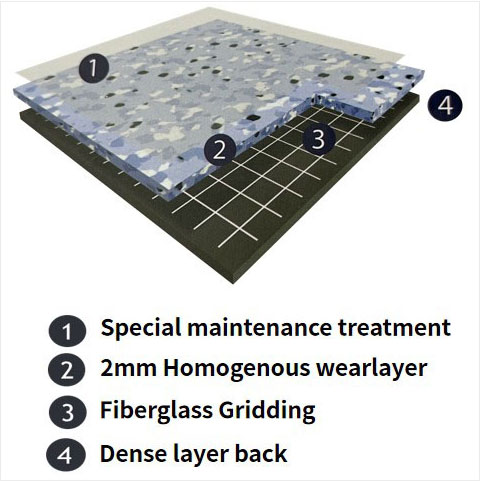

Structure: Our ESD Vinyl Sheet Flooring is made of polyvinyl chloride resin, plasticizer, stabilizer, coupling agent and conductive material, etc., and conducts electricity through the static conductive network formed between the plastic particle interface, which guarantee the permanent antistatic function.

Size: 2m x 20m

Thickness: 2.0mm, 2.5mm, 3.0mm

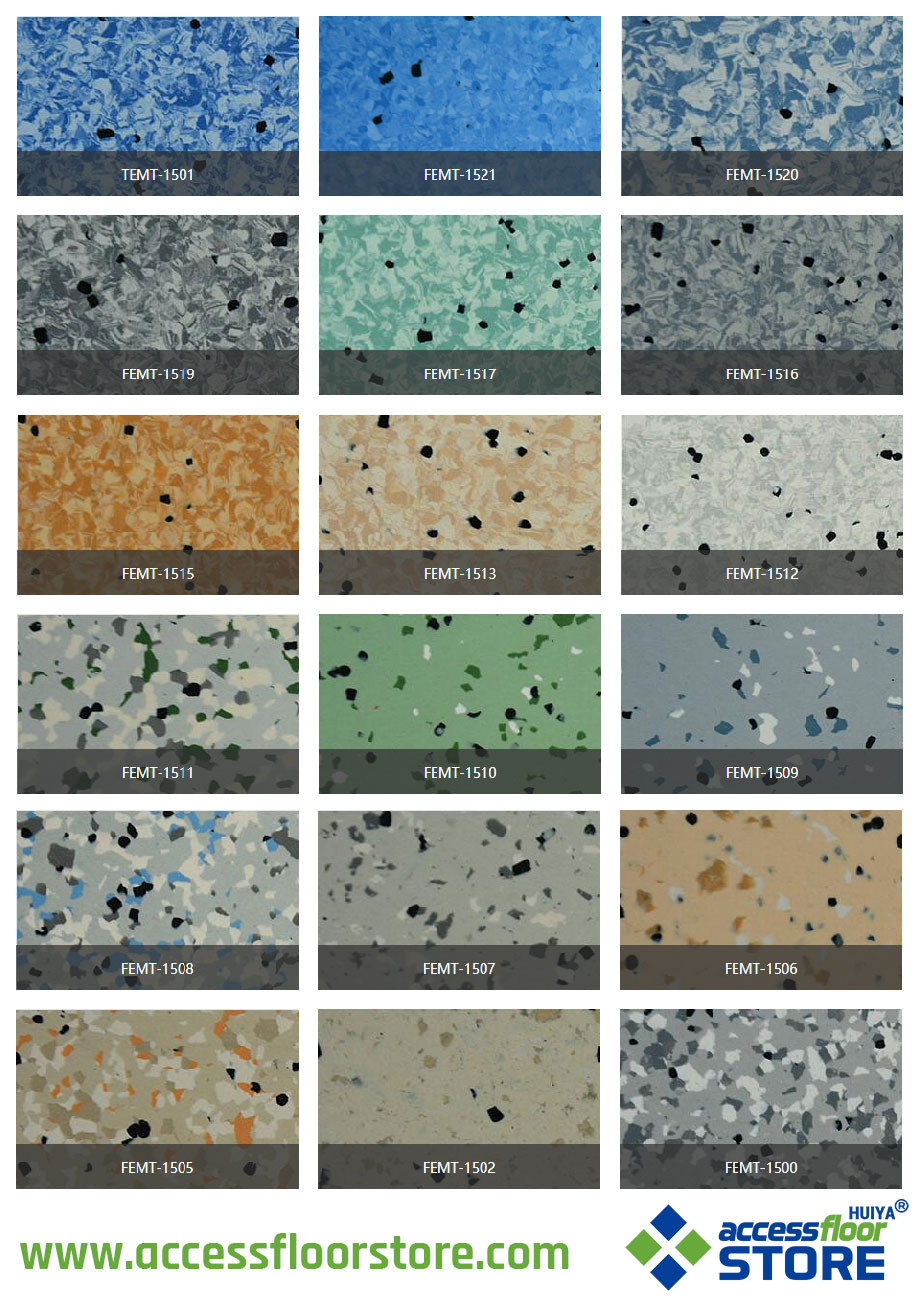

Various Patterns For Option

Wide Applications: Idea for office, electronics, microelectronics, telecommunications environment, network floor, clean room, computer room, operating room, assembly workshops and other places with precision instruments and equipment or the areas required anti-static floor environment.

Anti-Static PVC Flooring Roll (Vinyl Flooring Sheet) Advantages

Anti-static

Flexible homogenous vinyl flooring sheet

Special maintenance treatment: NO wax for life

Densely compacted homogeneous floor covering for improved wear and ease of maintenance

Incorporate bacteriostatic and fungistatic actions

Excellent performance of iodine

Durable and long-lasting, easy to clean

Designed to withstand large temperature changes

Easy to cut for an exact custom fitting, install in a short time

Quality Control and Assurance of Our ESD Roll Vinyl Flooring

All ESD PVC Floor Rolls are tested for electrical conductivity before it leaves the factory and meets quality standards.

Professional construction technical support and guidance provided.

Free of defects in materials and workmanship, 10+ years of server time (except for man-made and self-construction) can be guaranteed under proper installation and maintenance.

Benefits of Our Anti-Static Vinyl Floor Sheets (PVC Floor Rolls)

Available in the widest range of floor covering patterns and colors of any category.

Our Anti-static PVC Flooring Rolls are very affordable and prove to be a very profitable investment.

Its easy maintenance and its reasonable cost make it a choice often appreciated by consumers, especially for the raised floor projects in clean room, computer room, server room, telecommunications.

With our anti-static roll vinyl flooring, you get the best price and the fastest installation, although it is typically the least authentic look and feels.

what is conductive esd homogeneous vinyl flooring?

conductive esd homogeneous vinyl flooring is a flooring product that is composed of the following: homogeneous vinyl flooring with conductive carbon polymer to protect it from static electricity, its main use is for semiconductor manufacturing areas to help prevent electrostatic field emissions during equipment cleaning.

The conductive esd homogeneous vinyl flooring usually comes in rolls and can be purchased as an anti-static flooring installation kit. It can also be purchased as a conductive tile, sheet, or tape and applied to the floor as an anti-static area where sensitive electronic components are manufactured and handled; or even in areas where parts that may cause electrostatic damage during assembly and testing such as production facilities and laboratories where wafers and other semiconductor products are manufactured and tested.

The conductive esd homogeneous vinyl flooring is also used in other industries such as clean rooms and areas where ESD (electrostatic discharge) control is needed to protect sensitive equipment, like computer work stations: offices: printers: copy machines; copiers; fax machines; television screens; photographic film; counters: checkout areas for cash registers, credit card machines and other electronic equipment, or where sensitive electronic components are assembled.

Because the conductive material is heat resistant it can be used by many different industries especially the semiconductor industry, its main objective is to help prevent damage to sensitive electronic equipment due to electrostatic field emissions during equipment cleaning.

A conductive floor is usually composed of a vinyl release agent (floor covering) with carbon polymer for static control, the surface resistance is 10^6 ohms or less along with no accumulative effect conditions should occur to create potential problems. However, if there are any problems moisture must be eliminated to prevent short circuits since water conducts electricity.

What are the benefits of conductive ESD homogeneous vinyl flooring?

Conductive ESD smooth tile systems are designed for use in cleanroom environments. The surfaces are constructed with a polymeric resin system that has been either ionomer or metalized, giving them excellent printability and wear resistance for long-lasting beauty. These systems are available in a wide range of colors and offer excellent ESD protection per ASTM-C 1048, it meets or exceeds ANSI/ESD S20.20 with the lamination of an Antistatic Vinyl Flooring over the top surface of tile system can prevent electrostatic build-up on the surface of the floor.

Why need to use conductive esd homogeneous vinyl flooring?

In the IoT age, the need for ESD protection is becoming increasingly important as more and more devices are being built with sensitive circuits. The most common method of ESDS protection is to use a human body model (HBM) discharge unit. However, there are several drawbacks to this type of system that cannot provide sufficient protection from all types of ESD events.

The biggest drawback to using an HBM system is that it cannot be used in areas where the flooring material conducts electricity. An ESD event can create significantly high currents through conductive materials, so when they're not properly managed they can cause severe damage to sensitive equipment. At West Florida Flooring, we offer several homogenous vinyl flooring options as well as tiles to help solve this challenge. ESD homogeneous vinyl flooring is a non-conductive, air and vapor barrier material that can be used for easy ESD protection in all types of work areas.

Additionally, esd buildings offer major benefits including improved quality and efficiency, improved safety, better morale, and a more inspiring work environment.

why you should buy homogeneous vinyl flooring manufacturers in china?

- A homogeneous vinyl flooring manufacturers in China will last for a long time.

- It is also machine washable, so you can clean it without too much trouble.

- It has good stain resistance making it easy to clean any dirt or spills on the floor.

- These floors are very popular due to their maintenance-free nature.

- When purchasing homogeneous vinyl flooring manufacturers in china, make sure you buy from a company that has been around for a while and is well established.

- This will ensure you are buying a good quality product that will last.

- To be honest, I like manufactured wood floors as they can be stained to match any decor and they are easier to clean than carpeting.

- But if you do decide on wood, make sure it is at least 3/4 inch thick (or thicker) so the floor won't warp or crack in areas that get hot like near a door or where two walls meet. Here's one thing I don't understand about vinyl flooring:

- It claims to be non-slip while at the same time warns that it is not a good surface for wet areas.

- How can a floor be non-slip, but not safe in a wet area? Isn't water by its very nature...well...WET?

- If you spill something, wipe it up quickly and you should be fine. - Another thing I don't like about vinyl flooring is that to install it, the underlayment behind the walls has to be ripped out and replaced with a backer board which leaves a big mess in your living area...

- ...so we often take our home improvement projects outside when at all possible.

- This is especially important if your subfloor isn't solid because you'll end up with squeaky floors no matter how well you install the vinyl.

- I know...if you can't rip out the wallboard, at least remove the baseboards so they don't get damaged or paint will not be messed up during the install...

- ...but it always leaves the walls looking crappy since you can't properly finish them until all the work is done.

Application of conductive homogeneous vinyl flooring?

Conductive homogeneous vinyl flooring is most commonly used in industrial settings, where people are around electrical equipment that may release electrons into the air. It is also used in buildings with high traffic of vehicles due to its resistance against wear and tear.

The flooring is most often glued directly onto concrete or wood subfloors via heat welding, but it can also be laid over existing floors by the method of rolling.

The conductivity of the vinyl flooring is necessary because electrons are easily transferred through metals or conductive materials. People are safe near electron-emitting devices as long as they are far away from them, and there is no possibility of transferring electrical current to their feet. As long as your shoes or any other material between you and the floor is not conductive, there will be no problem.

The vinyl flooring can come in different thicknesses to allow for more strength in heavy-duty areas, but it generally comes in standard 4 millimeters or 8 millimeters. For high traffic areas, thicker is better, but there are so many kinds of businesses that the flooring can be used in most workplaces.

One reason why self-adhesive vinyl flooring is so popular in industrial settings is that it doesn't have to be glued down, which means it's easier to move out of the way when necessary. However, the conductive vinyl flooring is tough, and it doesn't melt under high temperatures.

Vinyl flooring isn't necessarily expensive; for example, one 4-millimeter roll contains 54 square feet of material that costs $12.85 per roll. If you consider the cost of carpeted floors in industrial areas, this product is quite inexpensive.

Other than electrical settings, conductive vinyl flooring is used in the medical field, where there are machines that emit electricity or radioactive waves. It can also be used outside in areas affected by de-icing salt. If you're around any potentially dangerous equipment all day at work, it's better to stay safe and purchase conductive vinyl flooring.

In addition, conductive homogeneous vinyl flooring can be used in homes or garages. There is no reason to have exposed wiring when you have a family, so it's best to cover it up whenever possible. If children are navigating your house, they could get a nasty shock if there was exposed wiring lying around on the floor.

When purchasing conductive homogeneous vinyl flooring, it's important to consider where you're going to lay it down. Make sure that the area is clean and dry before laying the product down, because if there are grease or water spots on the surface, they may transfer onto the vinyl flooring.

Conductive homogeneous vinyl flooring can be used in many different workplaces. It's important to consider the safety of your staff, and this type of flooring ensures that they are protected from electrical equipment that emits electrons into the air.

How to install conductive homogeneous vinyl flooring?

1. Work out the area and cut your material to size before removing any adhesive or backing paper. The vinyl flooring should not be larger than about 10% of the total room area, as this can lead to thermal bridges between different parts of the floor.

2. Lay the starting edge against a wall (or another straight line), with the vinyl facing down. Remove any adhesive from the flooring by drawing over it with a plastic scraper, which will also smooth out the backing paper and improve adhesion to concrete or other surfaces.

3. You can now start laying your vinyl, making sure your inside edges are straight and correct. Shown here is a patented 'Z' foot roller which can be used to press the vinyl into place for a better grip.

4. Use a plastic scraper or another straight edge as above, and run it along the wall to remove any air bubbles from under the vinyl flooring. Then check the cut-outs around piping, phone lines, etc - these should have been made during measuring and cutting.

5. When finished, walk across the vinyl flooring several times to compress the adhesive beneath, then wipe over it with a damp cloth and leave for between 24 and 48 hours.

6. If there are any gaps around the edges of the vinyl flooring, you can use an industrial double-sided tape or specialist 'gluing trowel' to seal it.

7. Check the adhesive hasn't dried out any before applying the glue. If you do this too soon, the adhesive could dry out and not provide an effective bond between your floor covering and your substrate (the base material). You should then be able to remove any residual paper or other packing materials from your vinyl flooring.

8. Finally, you will need to check the temperature of the room before laying your new floor covering, as a minimum temperature of 16 degrees Celsius is required for most types of commercial flooring adhesive to work properly.

what is the warranty of conductive homogeneous vinyl flooring?

The warranty of conductive homogeneous vinyl flooring is 1 year. The warranty of conductive vinyl flooring is 5 years. In many states, both homogeneous and patterned vinyl flooring has a 1-year warranty from the date of installation under normal residential usage conditions against seam separation, peeling/lifting, and buckling. The warranty against blistering and curled edges is for a period of 1 year, while the warranty against cracking and breaking extends for 3-5 years depending on the manufacturer.

The duration of the warranty depends on the conditions, such as normal residential usage conditions. There should not be abrasive cleaners or heavy traffic patterns. If it is found to be within the warranty guidelines, then the entire flooring surface must be replaced. This might seem like a hassle and may not necessarily meet one's expectations for an ideal solution; however, there is no other recourse available if manufacturers do not honor their warranties.

The only way many manufactures will replace the whole floor is by using their "abuse process". This doesn't mean you must abuse the floor, but it means that your expectations for its use are so great/harsh that they cannot reasonably expect to replace individual planks. To avoid this, be sure to read the warranty information carefully before making a purchase. The warranty process includes submitting proof of purchase and proof of installation.

Warranty is included with all Juno products. It is not limited to any specific period, but rather covers the product for as long as the original purchaser owns it - essentially preserving your rights of ownership.

The warranty covers material and workmanship defects that render the product unserviceable or unsafe under normal usage conditions. The warranty does not apply to the following:

a. Wear - it is assumed that flooring will wear under normal use conditions and replacement parts are available for purchase should this occur.

b. Damage caused by unauthorized repair or attempted repairs. The warranty will be void if any attempt has been made to replace components without authorization from Juno Corporation, Inc.

c.Damage caused by use of the product in a manner other than for which it was designed.

Damage to finish or discoloration from abuse, neglect, tampering, accident, alteration, improper installation, and maintenance, or any damage due to causes beyond our control such as continued exposure to sunlight and ultra-violet light sources over an extended period.

Damage or deterioration from condensation spills or improper cleaning methods.

Scratches caused by dragging furniture over the flooring surface with nails, metal objects, plastic soled shoes, etc.

Vinyl film damage results from exposure to certain chemicals such as common household products containing acids, alkalines, bleach, alcohol, ammonia, etc.

Vinyl flooring is not recommended for use in high-moisture areas such as bathrooms or showers. If it becomes wet, dry off completely before allowing excess water to evaporate naturally without drying with a fan or heater.

Proper installation and maintenance must be followed to avoid any problems from water or excess moisture.