NEWS TAG

brand

- Home

- Product List

- Calcium Sulphate Bare Raised Floor

Sell Type: International business

Product Attributes:

Email: [email protected]

WhatsApp: +86 18018280738

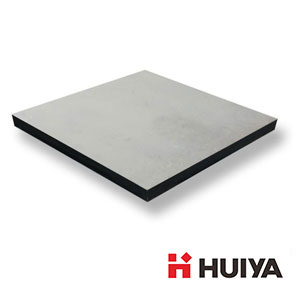

Calcium Sulphate Bare Raised Flooring

Calcium Sulphate bare raised flooring consists of high-strength calcium sulphate (calcium silicate or cement particle board) core. None tile on the top and bottom steel is bonded to the core with profiled edges.

Panel Specifications

Panel Class: Calcium Sulphate bare raised flooring Panel Type: CS5 / H33 Panel Dimensions: 600 x 600 mm Panel Thickness: ~ 33 mm Top Covering: none Bottom Covering: Aluminum sheet Edge: ABS edge band Panel Weight: ~ 8,50 kg/panel System Weight: ~ 25,35 kg/m2 (For height 15-20 cm) Panel Core: 30 mm high-density chipboard Fire Reaction: Bfl-s1 |  |

Panel Load Values (according to EN 12825)

Working Load: 1,5 kN

Maximum Load: > 4,00 kN

Safety Factor: 3

Panel Load Deflection Class: 1B

Calcium Sulphate bare raised flooring

As we are a manufacturer of premium quality floor systems with a long lifetime for more than 25 years, a responsible approach of humans and nature is a given. We are continuously optimizing our wide range of floor systems with the aim to even further reduce their impact on the environment over their entire life cycle. Every production step is subject to a thorough control of the ambitious energy, material and quality requirements – from the raw material to the ready-to-use system – thanks to the high vertical range of manufacture with LIGNA floors at the headquarters in Arnstorf. It is therefore safeguarded that our clients do not only receive a technically well-engineered product but also that they can rely on its ecological suitability, for example by the use of low emission components. The harmlessness of all Lindner floor systems to people's health has been proven by test chamber measurements. The results of a life cycle assessment of the site in Arnstorf have been incorporated in an Environmental Product Declaration according to ISO 14201, which is available for the verification of the environmental performance of Lindner LIGNA.